Driers & Valves

What is a drier and why does a system require it?

The drier is used on many a/c systems. It receives refrigerant from the condenser. The drier is mounted either adjacent to the condenser or somewhere in line before the expansion valve. It consists of a tank, a filter, a drying (agent) desiccant, a pick up tube, and a sight glass (on some applications) it has several functions.

First the drier acts as storage tank. It receives the liquid refrigerant from the condenser and holds this liquid until the evaporator requires it. Requirements vary according to operations conditions.

Second the drier acts as a protection agent for the system. The portion of the drier that contains the desiccant absorbs moisture from the refrigerant. The desiccant is usually in the form of silica gel. It is important that the moisture be removed from the system, as it can be extremely harmful to the air conditioning system components and to the systems operation. The sight glass is not used with R-134a, it was used on vehicles made before 1994 that used R-12 freon.

ACCUMULATOR

When an accumulator is present there is not a drier in the system, they perform the same function. The accumulator is mounted in the low side of the system, at the outlet of the evaporator. The function of the accumulator is to store (accumulate) refrigerant and to filter and dry the refrigerant. The accumulator also contains a desiccant. If any liquid refrigerant passes out of the evaporator the accumulator will store it. Liquid refrigerant is harmful to the compressor. Moisture is also harmful to the air conditioning system.

Why Change the drier or accumulator?

It is the job of the drier or accumulator’s desiccant to remove the moisture that may enter the system. If too much moisture enters the system (due to component malfunction or hose leakage), the desiccant will have to be replaced. This replacement may require complete replacement of the drier or accumulator because the desiccant is normally not removable.

The drier or accumulator should be changed if the system is opened, or a leak occurs, or if the system has the symptoms of having moisture in it. Moisture that enters an R-12 system will combine to form hydrochloric acid (HCL), which is harmful to the components. Moisture that enters the R-134a system will not form any harmful acids, but will lower system efficiency. R-134a in a liquid form will not absorb much moisture, but in a vapor state R-134a can absorb large amounts of moisture. On both systems (R-12 and R-134a) moisture can also gather on the expansion valve or orifice tube and freeze. This blocks the flow of refrigerant and prevents the cooling action at the evaporator.

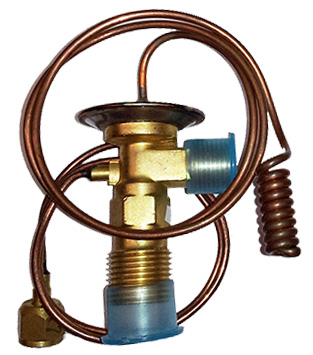

An expansion valve, which is located on the high side of the system, regulates the refrigerant going to the evaporator. The expansion valve will cause all of the refrigerant to evaporate as it goes through the evaporator. The valve will cause the refrigerant to change from high pressure to low pressure as it passes through the evaporator. An expansion valve and an orifice will have refrigerant enter it at a high pressure, as the refrigerant passes through the valve the refrigerant flow will be restricted causing the refrigerant to “spray” out the other side of the valve. This allows the refrigerant to vaporize as it passes through the evaporator, causing it to exit the evaporator as at a low pressure.

What is a drier and why does a system require it?

The drier is used on many a/c systems. It receives refrigerant from the condenser. The drier is mounted either adjacent to the condenser or somewhere in line before the expansion valve. It consists of a tank, a filter, a drying (agent) desiccant, a pick up tube, and a sight glass (on some applications) it has several functions.

First the drier acts as storage tank. It receives the liquid refrigerant from the condenser and holds this liquid until the evaporator requires it. Requirements vary according to operations conditions.

Second the drier acts as a protection agent for the system. The portion of the drier that contains the desiccant absorbs moisture from the refrigerant. The desiccant is usually in the form of silica gel. It is important that the moisture be removed from the system, as it can be extremely harmful to the air conditioning system components and to the systems operation. The sight glass is not used with R-134a, it was used on vehicles made before 1994 that used R-12 freon.

ACCUMULATOR

When an accumulator is present there is not a drier in the system, they perform the same function. The accumulator is mounted in the low side of the system, at the outlet of the evaporator. The function of the accumulator is to store (accumulate) refrigerant and to filter and dry the refrigerant. The accumulator also contains a desiccant. If any liquid refrigerant passes out of the evaporator the accumulator will store it. Liquid refrigerant is harmful to the compressor. Moisture is also harmful to the air conditioning system.

Why Change the drier or accumulator?

It is the job of the drier or accumulator’s desiccant to remove the moisture that may enter the system. If too much moisture enters the system (due to component malfunction or hose leakage), the desiccant will have to be replaced. This replacement may require complete replacement of the drier or accumulator because the desiccant is normally not removable.

The drier or accumulator should be changed if the system is opened, or a leak occurs, or if the system has the symptoms of having moisture in it. Moisture that enters an R-12 system will combine to form hydrochloric acid (HCL), which is harmful to the components. Moisture that enters the R-134a system will not form any harmful acids, but will lower system efficiency. R-134a in a liquid form will not absorb much moisture, but in a vapor state R-134a can absorb large amounts of moisture. On both systems (R-12 and R-134a) moisture can also gather on the expansion valve or orifice tube and freeze. This blocks the flow of refrigerant and prevents the cooling action at the evaporator.

An expansion valve, which is located on the high side of the system, regulates the refrigerant going to the evaporator. The expansion valve will cause all of the refrigerant to evaporate as it goes through the evaporator. The valve will cause the refrigerant to change from high pressure to low pressure as it passes through the evaporator. An expansion valve and an orifice will have refrigerant enter it at a high pressure, as the refrigerant passes through the valve the refrigerant flow will be restricted causing the refrigerant to “spray” out the other side of the valve. This allows the refrigerant to vaporize as it passes through the evaporator, causing it to exit the evaporator as at a low pressure.

Showing all 31 results

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

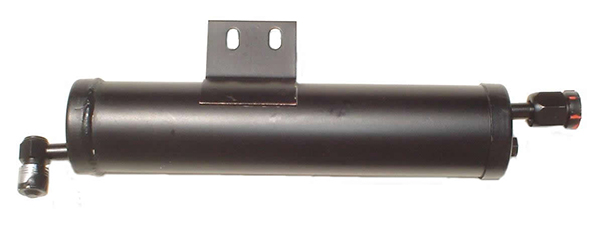

GM DRIER

SKU: 4-1020c $23.09 -

GM DRIER

SKU: 4-1021C $23.09 -

-

-

-

-

-

-

-

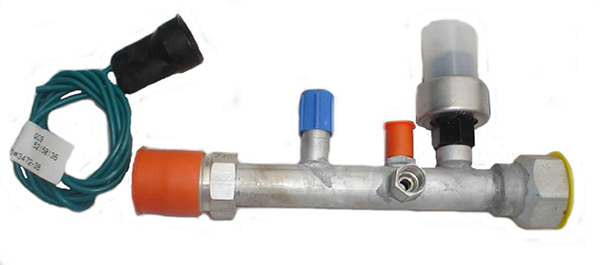

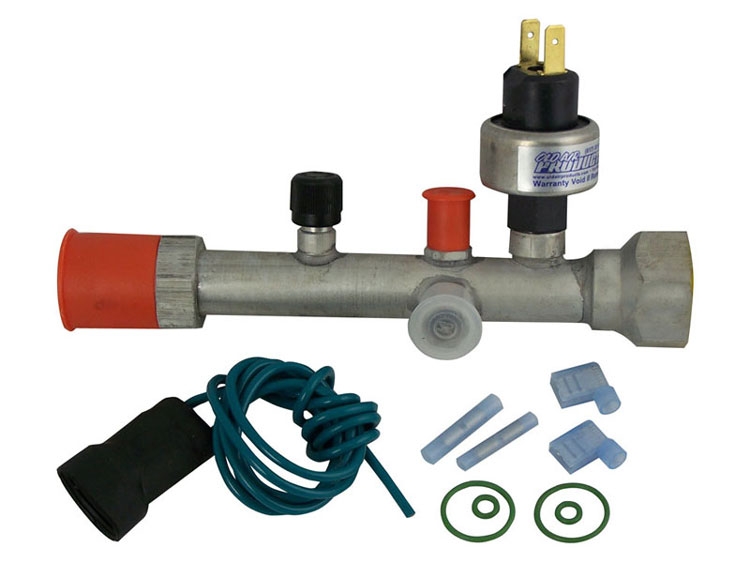

P.O.A. Eliminator

SKU: 94-9878 $132.81 -

-

-

-

-

-

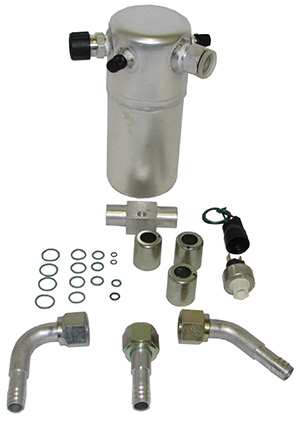

VIR Eliminator Kit

SKU: 4-1010 $109.71